Our Products

Value-engineered, international standards-compliant, and affordable products backed with decades of industry expertise to ensure 100% safety.

Explore MoreProduct Spotlight

Products of today, ready for tomorrow. A perfect combination of efficiency and affordability

Explore NowHSJW

Stabilizer

Three-Phase Voltage Stabilizer

Explore NowHDB3w

MCB

Miniature Circuit Breaker

Explore NowFlexo

Wiring Devices

Switches, Sockets, and Accessories

Explore NowSOLAR

VSD

Variable Speed Drive

Explore NowLED Highbay

Lighting

Industrial Lighting

Explore NowHP606

Meter

Digital Panel Meter

Explore NowOur Solutions

Meeting industry's expectations is our top priority.

Meeting industry's expectations is our top priority.

Explore Now

Our Solutions

Making your life easy and your home or facility manageable - anytime, anywhere.

Making your life easy and your home or facility manageable - anytime, anywhere.

Explore Now

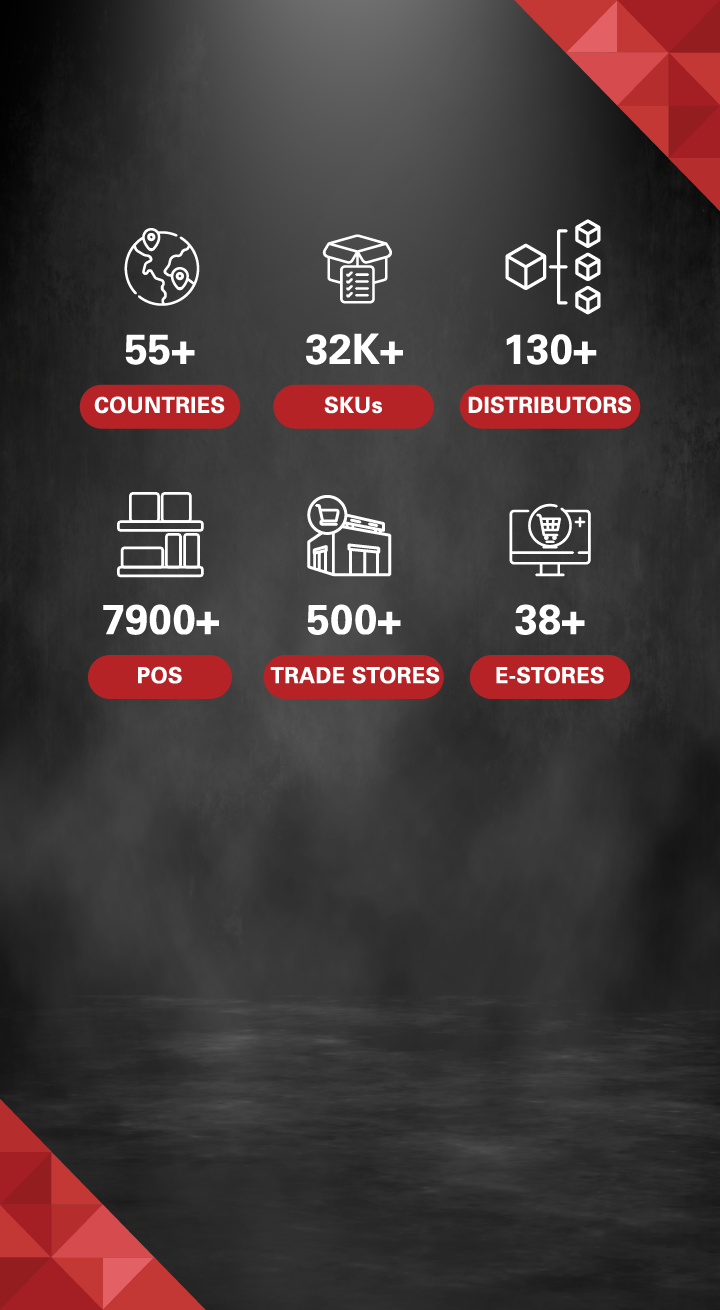

Why HIMEL?

Global + Local expertise for adding greater value to your engineering projects

Explore More